Water & FirePump Services

Reliable Water & Fire Pump Services You Can Count On

Certified Solutions to Keep Your Fire Protection Equipment Operating Safely

Specializing in comprehensive fire pump services to keep your systems compliant, functional, and ready when you need them most. With decades of experience serving the greater Chicagoland area, our team delivers expert inspections, repairs, and testing to ensure your fire protection system meets NFPA and insurance standards.

Annual Fire Pump Testing

Acceptance Fire Pump Testing

Fire Pump Repack

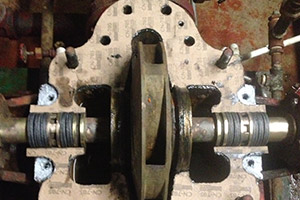

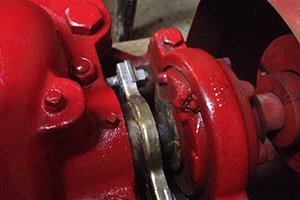

Worn or deteriorated packing can lead to excessive leakage, reduced pump performance, and premature wear on critical components often resulting in unplanned downtime and costly repairs. Our fire pump repacking service involves the removal and replacement of shaft packing, gland bolts and case gasket to restore proper seal integrity and regulate leakage in accordance with manufacturer recommendations and NFPA guidelines. By ensuring smooth, reliable operation, repacking helps extend the life of the pump, protects the shaft and bearings, and maintains overall system reliability.

Top off repack with bearing replacement

A top-off repack with bearing replacement addresses wear at the pump shaft and bearing assembly to restore proper operation and reliability. This service includes adding or replacing shaft packing, gland bolts and case gaskets as needed to maintain proper seal integrity, along with the removal and replacement of worn pump bearings. Replacing the bearings helps reduce vibration, improve alignment, and prevent further damage to the shaft and internal components. Once completed, the pump is checked for smooth operation and proper leakage, ensuring dependable performance and extended equipment life.

Top-Off Inspections

A fire pump top-off inspection is an interim evaluation performed to verify that critical components are operating within acceptable tolerances between major testing and maintenance events. The inspection includes checking lubrication levels, bearing condition, shaft and coupling alignment, packing leakage, vibration indicators, and wear ring tolerances. Identifying conditions that are approaching, or outside allowable limits helps prevent premature component wear, reduces the risk of unexpected failure, and can assist in investigating pump performance degradation or system issues.

Coupling Replacements

Fire pump couplings are critical for transferring power safely and efficiently from the driver to the pump. When replacement is needed, we use manufacturer-approved parts to ensure precise alignment, vibration-free operation, and optimal efficiency. Because coupling failure can cause extensive damage and system downtime, timely inspection and maintenance are essential to keep your fire pump reliable and ready when it’s needed most.

Hydrant & Standpipe Testing

Regular hydrant and standpipe flushing removes sediment, scale, and stagnant water, helping ensure water quality and flow performance during an emergency. Our technicians follow NFPA 25 flushing guidelines to keep your fire suppression network clean, reliable, and compliant.

Water Pump Repairs

From seal failures and bearing issues to broken shafts and electrical faults, we repair all types of water pumps used in fire protection and industrial systems. Whether on-site or in our service shop, Rogers Pump provides expert diagnosis, precision repairs, and rapid turnaround to minimize your downtime.

Fire Pump Controller Replacement

The fire pump controller is the brain behind your fire protection system, and when it fails, your entire operation is at risk. Rogers Pump provides expert fire pump controller replacements to restore reliable startup, system monitoring, and safety functions. Whether you’re upgrading outdated equipment or replacing a faulty unit, we install UL-listed, NFPA 20-compliant controllers to keep your system code-compliant and ready to perform.

Fire Pump Replacement

When repairs are no longer cost-effective or your pump has reached the end of its service life, a full fire pump replacement may be necessary. Rogers Pump handles the entire replacement process—from system evaluation and pump selection to removal and installation. Our team ensures your new pump is properly aligned, performance-tested, and fully compliant with NFPA standards, giving you confidence in long-term protection and performance.

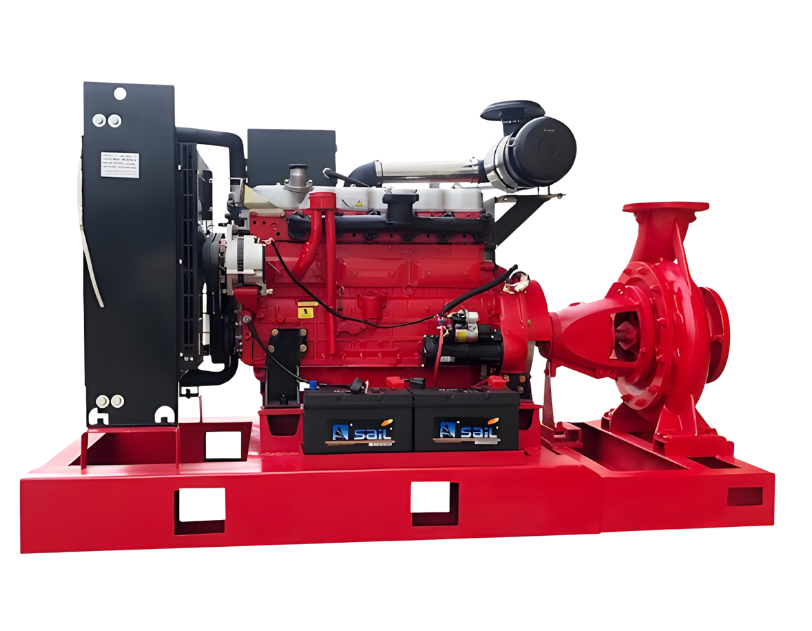

Diesel Fire Pump Engine Maintenance

Diesel fire pump maintenance is a comprehensive program designed to keep your diesel-driven fire pump ready for emergency operation. Our technicians inspect and service the engine, fuel system, lubrication, cooling system, batteries, and critical pump components. Routine maintenance identifies potential issues early, reduces the risk of unexpected downtime, and ensures compliance with NFPA 25 and manufacturer guidelines.

Annual Fire Pump Testing

Routine annual fire pump testing is essential to meet NFPA 25 compliance and verify your system’s operational readiness. We simulate real-world fire conditions to measure flow rates, pressure levels, and pump performance, providing full reports and recommendations for any necessary repairs. Trust Rogers Pump to ensure your system is inspection ready year-round.

Acceptance Fire Pump Testing

Before a new system is commissioned, acceptance testing verifies that your fire pump and components meet all required specs and manufacturer standards. We perform controlled flow tests, simulate peak demand, and document performance to certify system acceptance per NFPA 20 requirements. Whether it’s a new installation or major retrofit, we make sure it’s done right from the start.

Fire Pump Repack

Leaking glands or excessive wear around the shaft? Our fire pump repacking service restores pump efficiency and prevents costly water damage. We use high-quality packing rings and expert installation techniques to reduce leakage, protect your bearings, and extend pump life, all while keeping you NFPA 25 compliant.

Fire Pump Rebuild

When repacking isn’t enough, a full fire pump rebuild can return your equipment to like-new condition. Rogers Pump disassembles and inspects all components, replaces worn parts, machines new fits as needed, and reassembles to factory tolerances. Our rebuilds are ideal for extending pump life without the cost of full replacement.

Top-Off Inspections

Top-Off Inspections are interim checks to verify your fire pump system is operating correctly between major testing events. Our team inspects lubrication levels, checks alignment, verifies controller settings, and tests critical components to catch problems early, helping prevent failure when you need the system most.

Coupling Replacements

Fire pump couplings are vital for safe power transfer between the driver and pump. We inspect for wear, misalignment, and fatigue, then replace couplings using manufacturer approved parts to ensure vibration free, efficient operation. Coupling failure can lead to catastrophic damage, so don’t wait until it’s too late.

Hydrant & Standpipe Flushing

Regular hydrant and standpipe flushing removes sediment, scale, and stagnant water, helping ensure water quality and flow performance during an emergency. Our technicians follow NFPA 25 flushing guidelines to keep your fire suppression network clean, reliable, and compliant.

Water Pump Repairs

From seal failures and bearing issues to broken shafts and electrical faults, we repair all types of water pumps used in fire protection and industrial systems. Whether on-site or in our service shop, Rogers Pump provides expert diagnosis, precision repairs, and rapid turnaround to minimize your downtime.

Fire Pump Controller Replacement

The fire pump controller is the brain behind your fire protection system, and when it fails, your entire operation is at risk. Rogers Pump provides expert fire pump controller replacements to restore reliable startup, system monitoring, and safety functions. Whether you’re upgrading outdated equipment or replacing a faulty unit, we install UL-listed, NFPA 20-compliant controllers to keep your system code-compliant and ready to perform.

Fire Pump Replacement

When repairs are no longer cost-effective or your pump has reached the end of its service life, a full fire pump replacement may be necessary. Rogers Pump handles the entire replacement process—from system evaluation and pump selection to removal and installation. Our team ensures your new pump is properly aligned, performance-tested, and fully compliant with NFPA standards, giving you confidence in long-term protection and performance.

Diesel Fire Pump Engine Maintenance

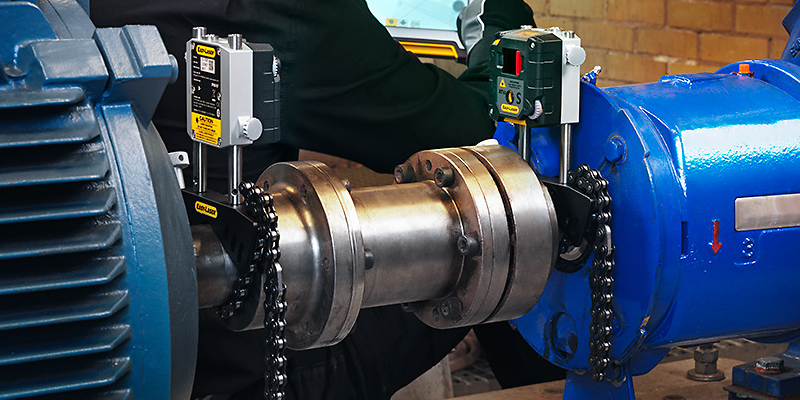

Pump Laser Alignment

Pump laser alignment is a precision procedure that ensures the shafts of a fire pump and its driver typically an electric motor or diesel engine are perfectly aligned using advanced laser tools. This service is essential during installation, repair, or maintenance to optimize coupling performance, reduce vibration, and prevent premature wear on bearings, seals, and shafts. At Rogers Pump, our technicians perform laser alignment with exacting accuracy to maximize pump performance, extend equipment life, and maintain compliance with NFPA and manufacturer specifications.

Benefits of Laser Alignment

Precisely aligns pump and driver shafts

Reduces the risk of failure during emergency full-load operation

Prevents excessive vibration caused by misalignment

Helps avoid loosening of components

Minimizes operator discomfort

Prevents early failure of nearby equipment

Extends the life of bearings, seals, and couplings

Reduces radial and axial loads that cause early component failure

Decreases resistance and friction from misalignment

Improves overall system efficiency and reduces power loss

Lowers the risk of mechanical breakdowns

Prevents hot surfaces caused by friction

Enhances reliability during emergency conditions

Promotes safe operation for personnel and building occupants

Key Maintenance Services

Routine visual and operational checks to identify wear, leaks, corrosion, and potential mechanical issues before they become costly failures.

Timely replacement of engine oil, oil filters, and fuel filters to maintain optimal engine lubrication and fuel quality.

Inspection and servicing of radiators, coolant levels, hoses, and belts to prevent overheating and engine damage.

Ensuring batteries are fully charged and starter motors are functioning correctly to guarantee reliable engine starts during emergencies.

Checking fuel tanks, lines, injectors, and pumps for contamination or blockages that could impair engine performance.

Verifying exhaust components are intact and free of obstructions, ensuring safe engine operation.

Conducting load and operational tests to confirm the diesel engine delivers required horsepower and meets performance specifications.

Detailed reports on all maintenance activities and test results to assist with NFPA compliance audits and insurance inspections.

Ready to Schedule Service?

Whether you need a routine inspection or emergency repair, Rogers Pump is here to help.

Contact us today to schedule your service or speak with a technician about your fire protection system needs.